| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : WELLDONE

Model Number : PZG-(500-12000)

Certification : CE, ISO 9001: 2008, ISO 10004

Place of Origin : China

MOQ : 1Set

Price : 11000 USD to 200000 USD

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10Sets/Months

Delivery Time : 30-60Working Days

Packaging Details : Wooden Case + Plastic Film + Steel Frame

Voltage : 110V/220V/380V/415V/480V

Hertz : 50HZ, 60HZ

Material : CS/SUS304/SUS316L/Titanium

Installation Power : 5.5KW-85KW

Drying Temperature : 50-150℃

Weight : 0.8Ton-40Ton

Heating Resource : Steam/Thermal Oil/Hot Water

Drying Efficiency : 80%

Way to Control : Button/Touch Screen/Remote

Special Design : Explosion Resistance/Low Temperature Drying

Loading Capcity : 150KGS/Batch-8000KGS/Batch

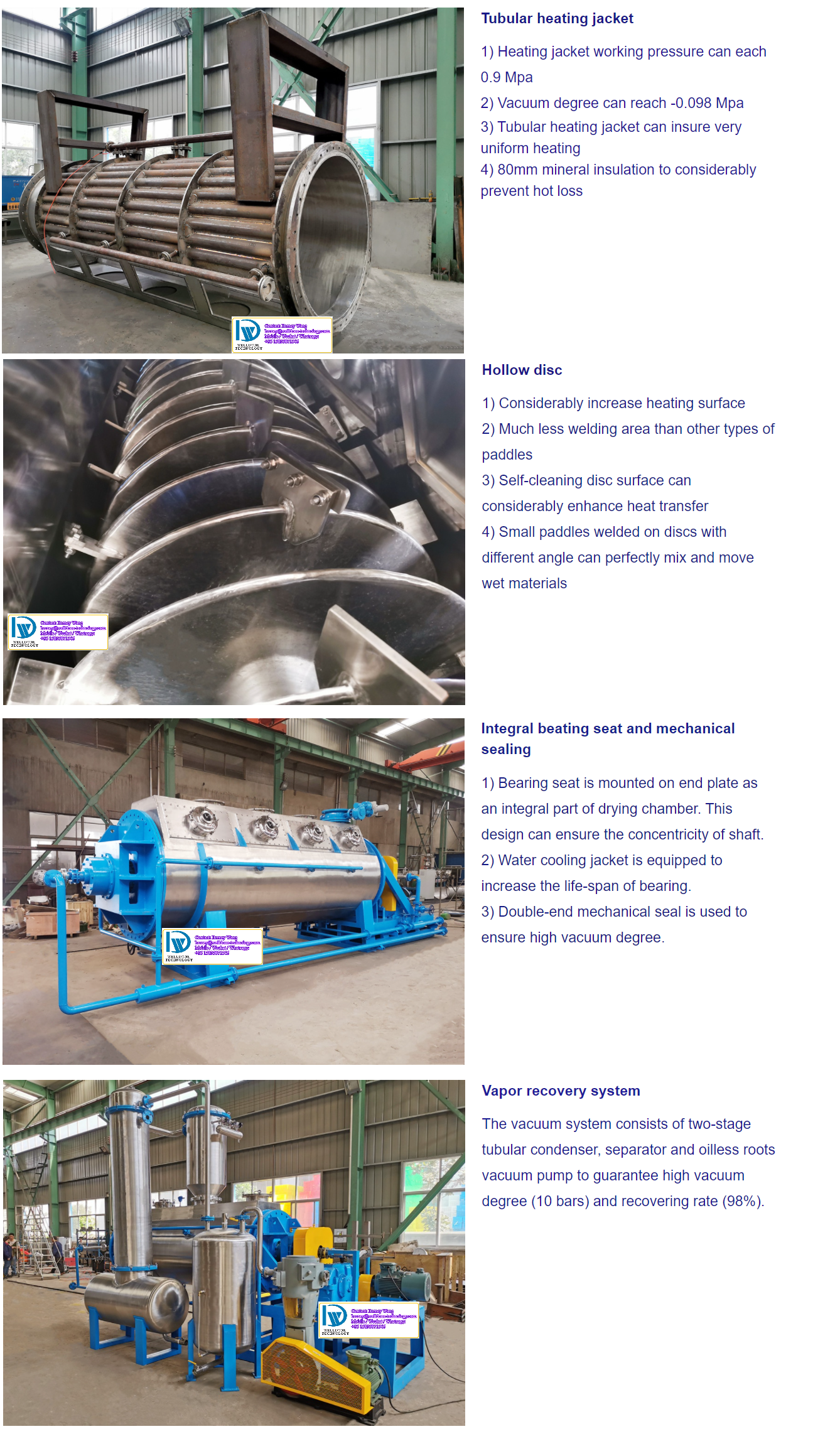

Disc type vacuum paddle dryer adopt the paddle of round disc, it has larger drying area than regular design, the drying speed is much faster, and it just occupied much less space.

1. Used for drying or reacting of pastes, filter cakes, powders, and granules under vacuum condition;

2. Heating area: 10-300 M2

3. Volume of drying chamber: 500-25000 L

4. Working type: Batch type or continuous

5. Heat source: steam, hot water or hot oil

PZG series rotary vacuum paddle dryer is an indirect heating drying processor which gives drying, mixing and breaking effects simultaneously. Wet cake or slurry is fed through feed port. The main shaft with hollow discs rotates in different directions to regularly move and mix the material, while vacuum is applied in the dryer and heating media is circulated in the jacket of drying chamber and hollow discs. Evaporation of moisture takes place under vacuum condition and vapors passes through the dust catcher into the condenser, where it is condensed and collected in the receiver. Dried material is discharged through discharge valve.

ZPG series vacuum paddle dryer has been widely used for drying wet cake product after filtration especially sticky heat sensitive paste material. This equipment can be used in drying process of various Pharmaceuticals, Intermediate Compounds, Fine Chemicals, Chemicals, Agro Chemicals, Pesticides, Insecticides, Dyes and Food Products which have the following properties:

1) Powder, slurry, paste and filter cake wet materials;

2) Heat sensitive wet materials

3) Easy-oxidizing, toxic, explosive wet materials

4) Moisture is organic solution and need to be recovered

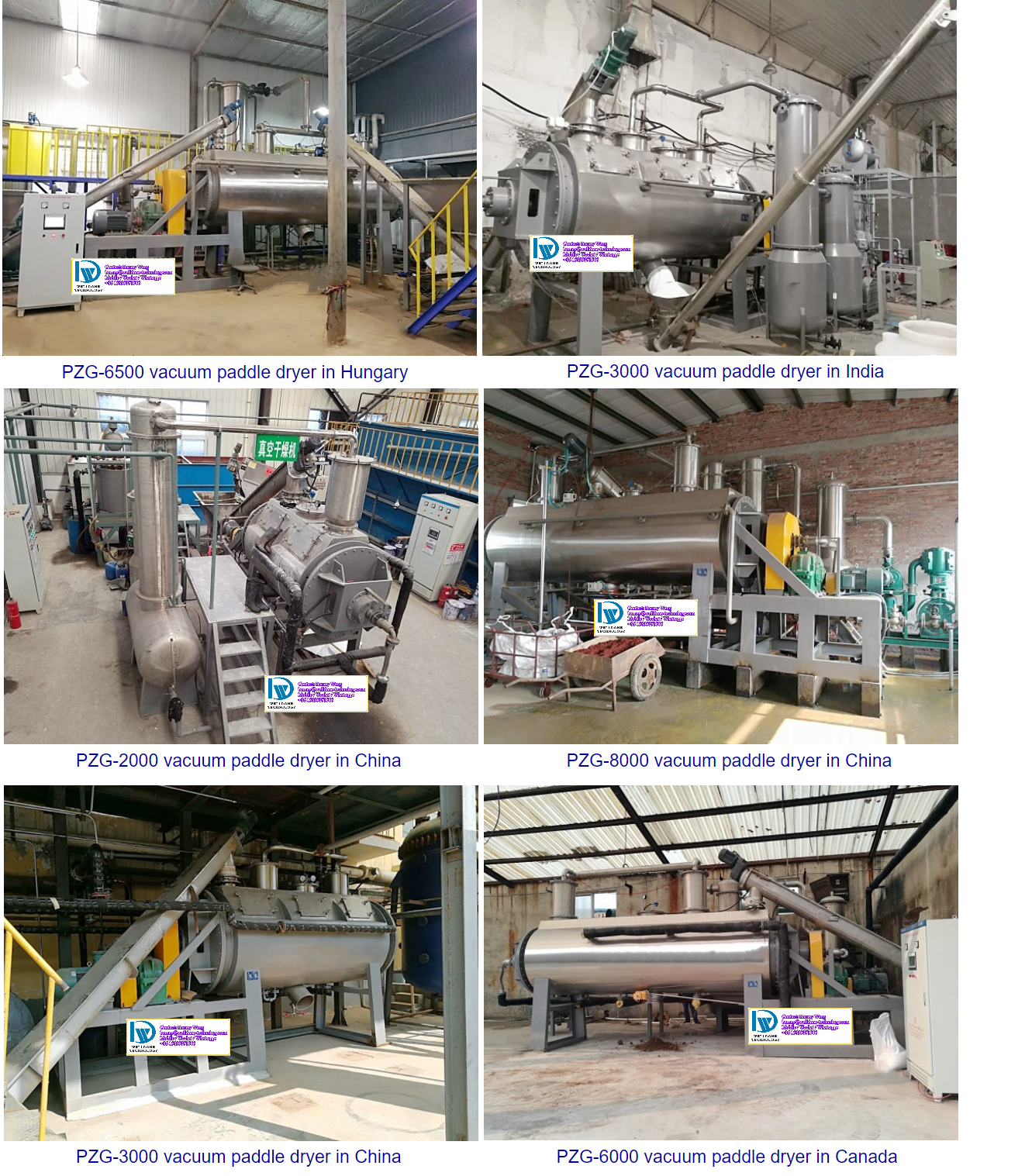

Picture of Vacuum Paddle Dryer in Working

|

|

Explosion Resistance SUS316L Industrial Vacuum Drum Dryer Images |